Open Mind will also be debuting an all-new Virtual Machining Center solution that uses NC code after the postprocessor run as a basis for the simulation, ensuring that virtual machine movements correspond precisely to real machine movement.Īttendees can also view new features/ functions on hyperMILL 2018.1 software release at the show. Hyper MILL software is available standalone with hyperCAD-S CAD for CAM, or integrated in SolidWorks or Autodesk Inventor. Hypermill enables CAM programmers to create NC programs. This ensures that a real component can be generated from. The system also allows the user to control the contact point to increase cutter life or to help reach in specific areas. Hypermill is a modular CAM software solution that is being developed by Open Mind Technologies. NC programmers use CAM software to create the control code for CNC machine tools.

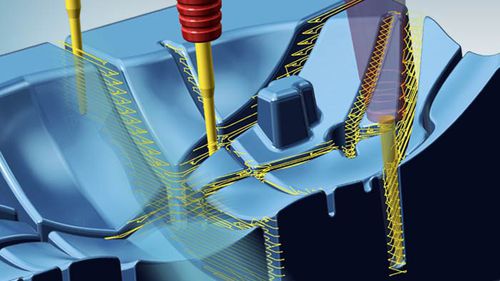

The large radius on conical barrel tools allow wider step-over, while the tool’s conical surface enables short cutters to be used with a collision detection process. MAXX Machining finishing applies conical barrel cutters to large surfaces – planar, ruled, or general. MAXX Machining drilling enables 5-axis helical motion to open pockets, with excellent chip removal using standard endmills. The 5-axis MAXX Machining roughing function is suited for engine casings and radial components. MAXX Machining roughing is based on the Volumill toolkit and has been applied to 2.5D pocketing, 3D roughing, and 5-axis roughing.

#Hypermill cam full

MAXX Machining provides a set of high performance strategies for roughing, finishing, and drilling, covering a full spectrum of machining functions from 2.5D through 5-axix milling and drilling, mill-turn, and specialty applications.

OPEN MIND Technologies will present hyperMILL MAXX Machining and other new CAM software solutions at EMO, Hall 25, Booth No.

0 kommentar(er)

0 kommentar(er)